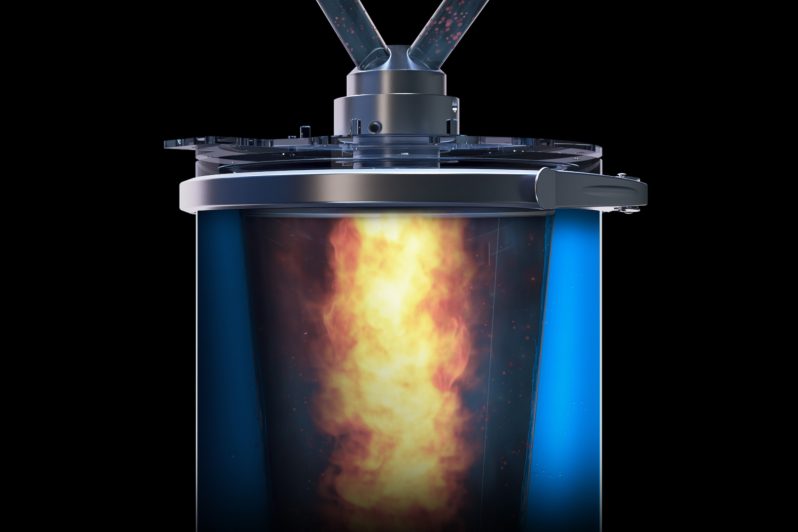

Thermal Gas

Treatment

High efficiency

and intelligent burner

Water flushed

and cooled

combustion chamber

Optional

addition of

neutralization

medium

Scrubber stage for

water-soluble gases

and particles